Now that the cam chain drive is set, I moved on to the oil drive system, which was a pretty simple reverse engineering of the OEM Panigale system. Same gears, same centers, so this was just a verification process.

Thoug it was just a verification process, it needed to be a lot more precise than the previous cam drive test. The hydraulic tensioner and floating guide of the chain drive system easily to compensate for the .005-.010″ error that could creep in during manual measuring, so the mockup did not need to be of extreme precision. The oil drive system is all gear, so generating precise center distances is required for verifying operation.

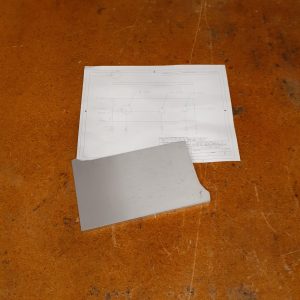

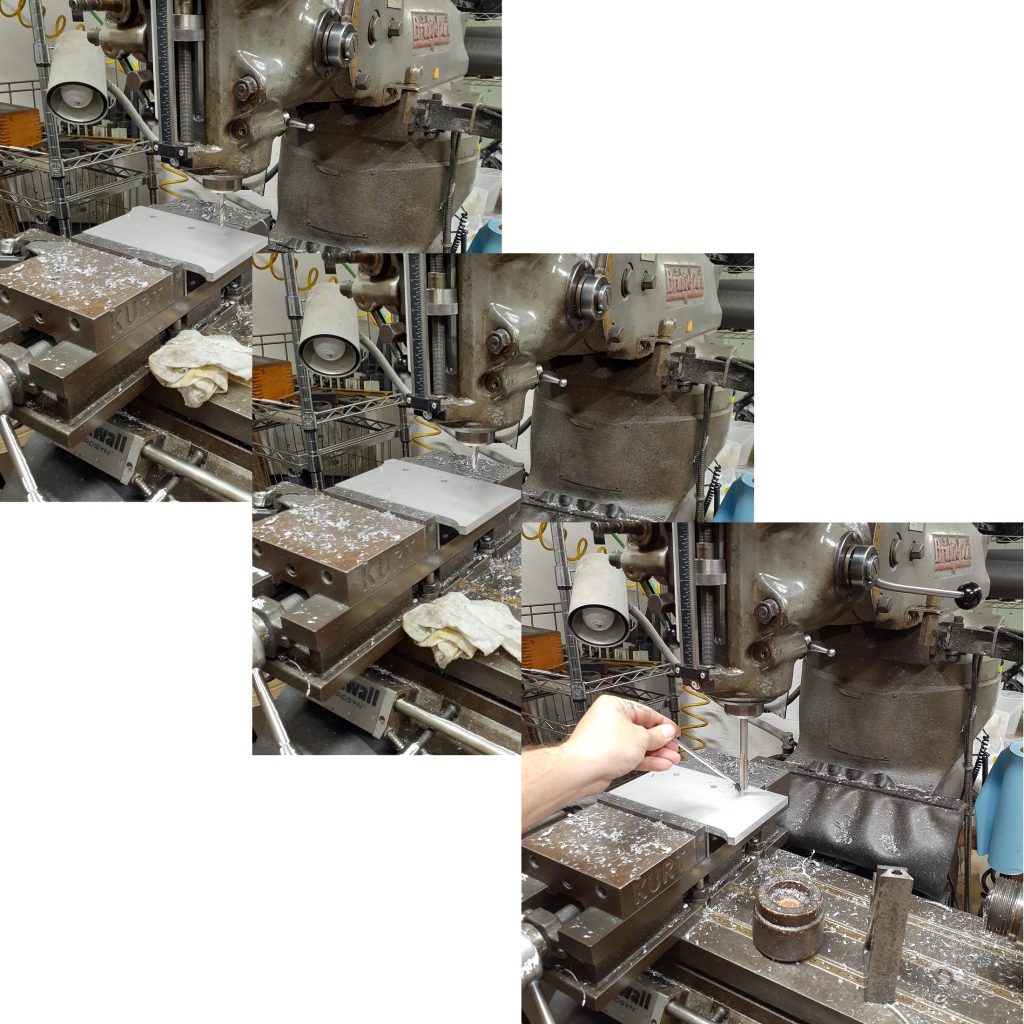

Starting with a piece of scrap and the center distance measurements…

It was on to the ‘ol Bridgeport mill to do a drill, end mill (with convieient undersize metric 2 flute end mill), and precision ream for each of the gear shaft bores:

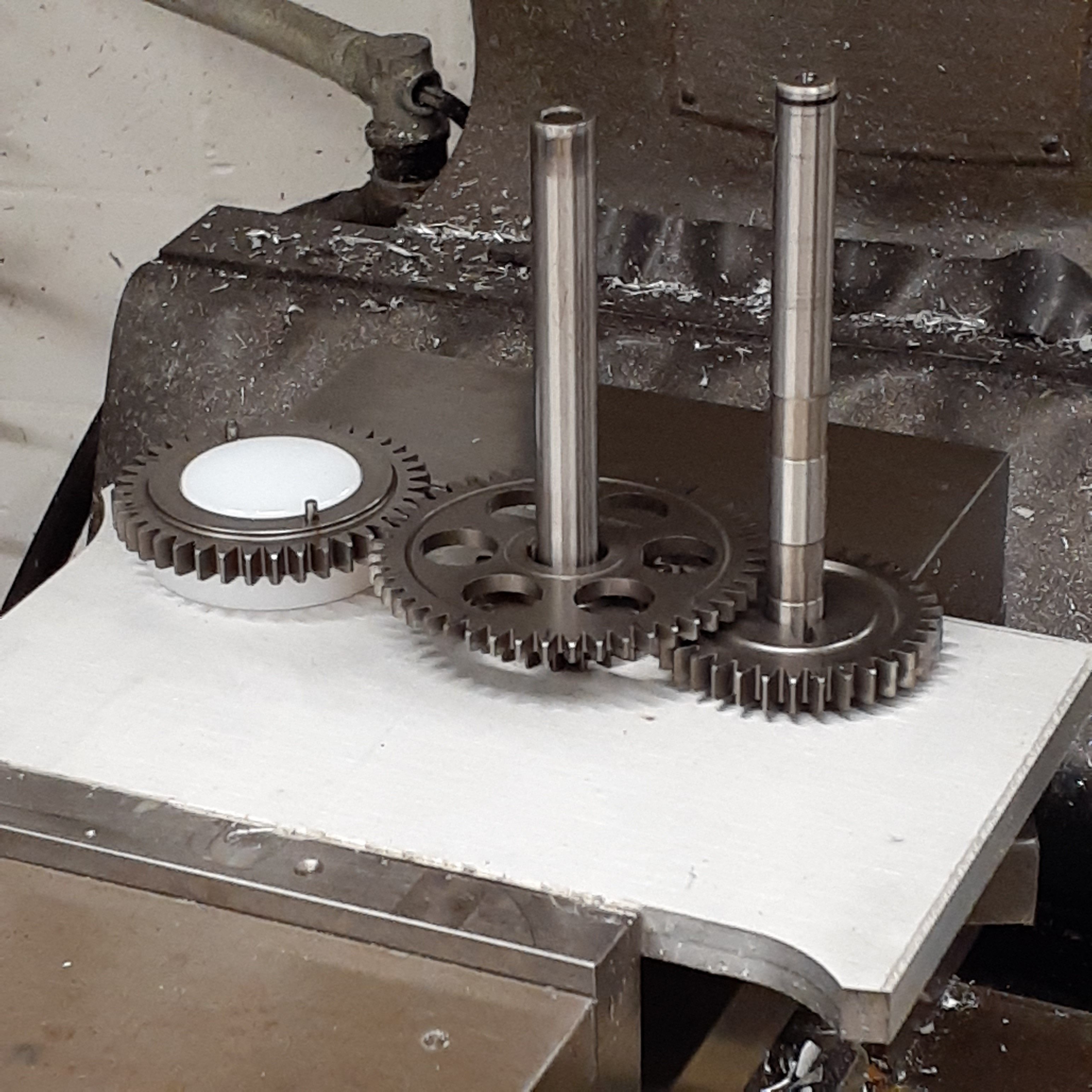

Then a quick delrin hub for the crank gear was turned up and the testplate assembled.

Each gear was shimmed to check the backlash and it was within .0005 of the OEM setup. Geometry verified. Just for a double check, a bit of shop air was used to spin it up and listen for any weird noise.

Success!

Next up is the starter geartrain, which is a little more complex since an idler gear is being added, so we have to try to match the weird OEM ‘Module’ with the new idler gear. To do this, expertise from Michael Moore’s motorcycle mailing list had to be called in. No, not the MM you are thinking. Michael Moore of eurospares.com, a veritible Svalbard Global Seed Vault for motorcycle technical and fabrication information. Fun Fun Fun! Details to follow.