From the inside to the outside, the previous post about the engine internal gearing leads to machining the magnesium engine cover and sump castings. Programming and fixturing for 3 sets of 3 parts cast by Curto Ligonier Foundries needs to be done.

The surfaces of the castings looked very clean, so I was hoping that the machining would not reveal any internal porosity.

The surfaces of the castings looked very clean, so I was hoping that the machining would not reveal any internal porosity.

First up was the left side cover. 3 parts and a bucket of sand in case of any ignition. Though machining was being done completely dry, there was not any heavy material removal so all I would need to do to avoid a fire was not to crash the tool into any of the steel fixture components.

Initial fixturing was intended to make it a one operation program, so the part was suspended from the fixture plate by knurled fixture points and aligned by locating on some internal round features. The fixture plate was mounted on my 9×23 Martin Trunnion table for a minimum of repositioning.

And is clamped in place for initial machining by some standard clamping bars on top of the support pads to avoid deflection.

And is clamped in place for initial machining by some standard clamping bars on top of the support pads to avoid deflection.

For the initial machining. Most of the cutting was done in a horizontal orientation, then it was turned to machine the oil fill port, which will be capped off with a JW Winco fill plug.

For the initial machining. Most of the cutting was done in a horizontal orientation, then it was turned to machine the oil fill port, which will be capped off with a JW Winco fill plug.

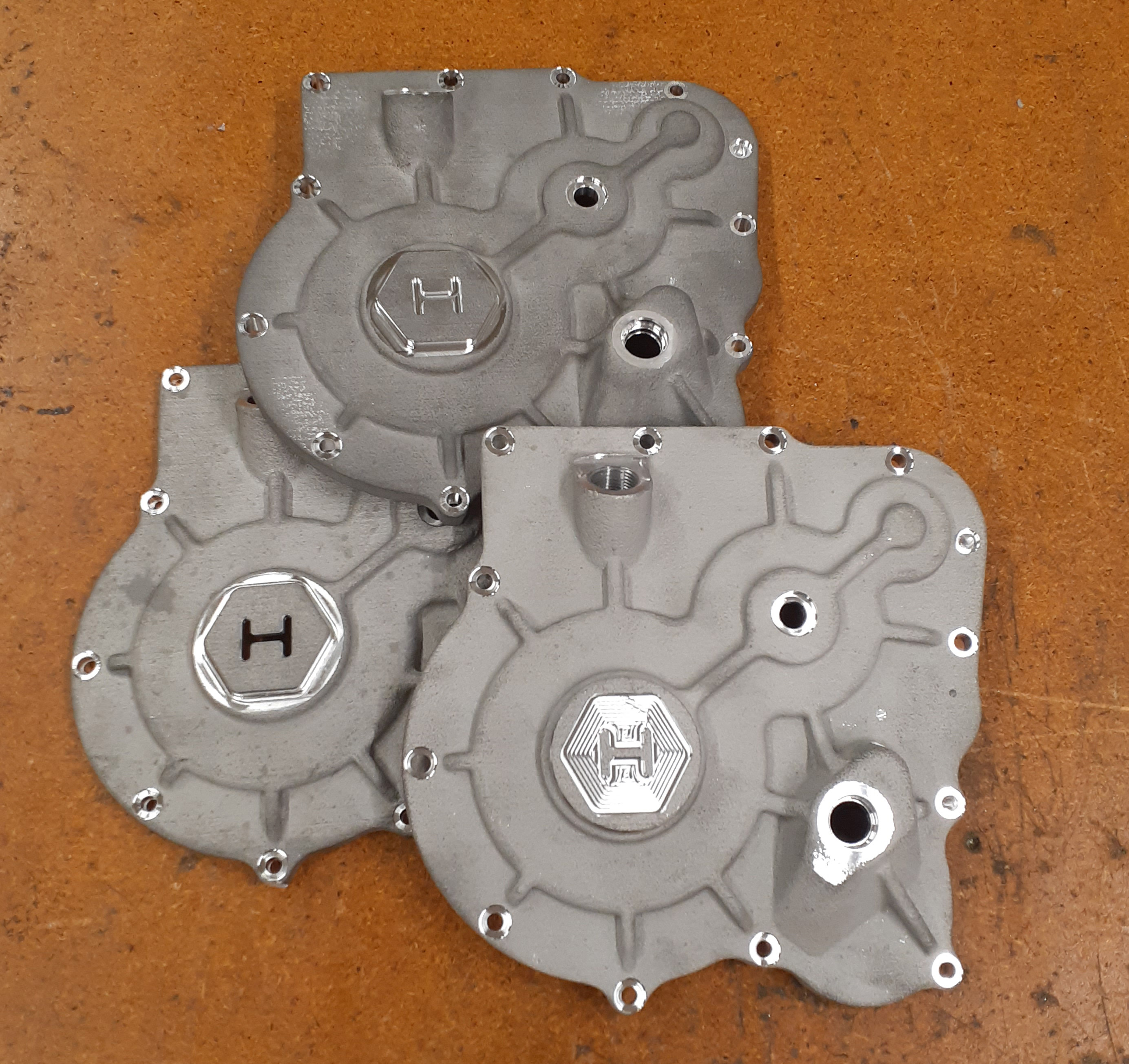

The surface finish after machining was amazing. No porosity to be seen. Sweetness!

The surface finish after machining was amazing. No porosity to be seen. Sweetness!

At this point, a profiled aluminum clamping plate replaced the standard clamping bars to allow for full perimeter access for what I hoped would allow for a side insert cutter to back-cut the gasket surface all in one operation.

At this point, a profiled aluminum clamping plate replaced the standard clamping bars to allow for full perimeter access for what I hoped would allow for a side insert cutter to back-cut the gasket surface all in one operation. Unfortunately that did not work out as well as I hoped. The part/material combination was just not stiff enough to allow for any overhang when machining. Plan B was now implemented, using the same well-used baseplate fixture from the previous operation. An array of standoffs matching the bolt hole pattern and some internal clamping through the recently-machined holes provided support directly below the surface being machined.

Unfortunately that did not work out as well as I hoped. The part/material combination was just not stiff enough to allow for any overhang when machining. Plan B was now implemented, using the same well-used baseplate fixture from the previous operation. An array of standoffs matching the bolt hole pattern and some internal clamping through the recently-machined holes provided support directly below the surface being machined.

And after machining, see that gleam! Again, no porosity, a great feature for a gasket sealing surface.

And after machining, see that gleam! Again, no porosity, a great feature for a gasket sealing surface.

I ran each part, with some different options for the ‘H’ logo, including the one where I accidentally went too deep and broke through the material so will epoxy in some borosilicate glass.

I ran each part, with some different options for the ‘H’ logo, including the one where I accidentally went too deep and broke through the material so will epoxy in some borosilicate glass.

And what do you do with the magnesium chips? Hold my beer, I’ll show you:

And what do you do with the magnesium chips? Hold my beer, I’ll show you:

Next up is something different for a change of pace.