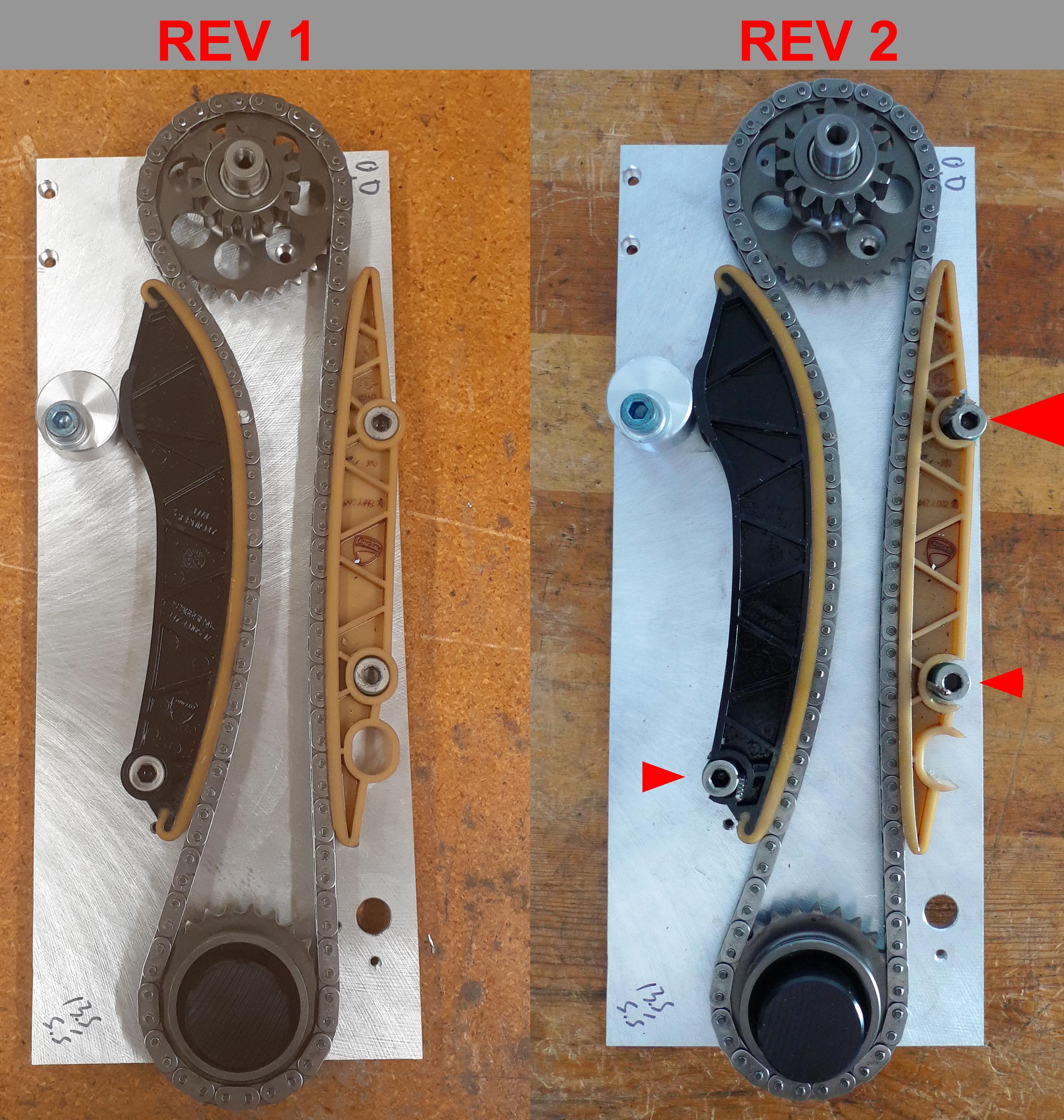

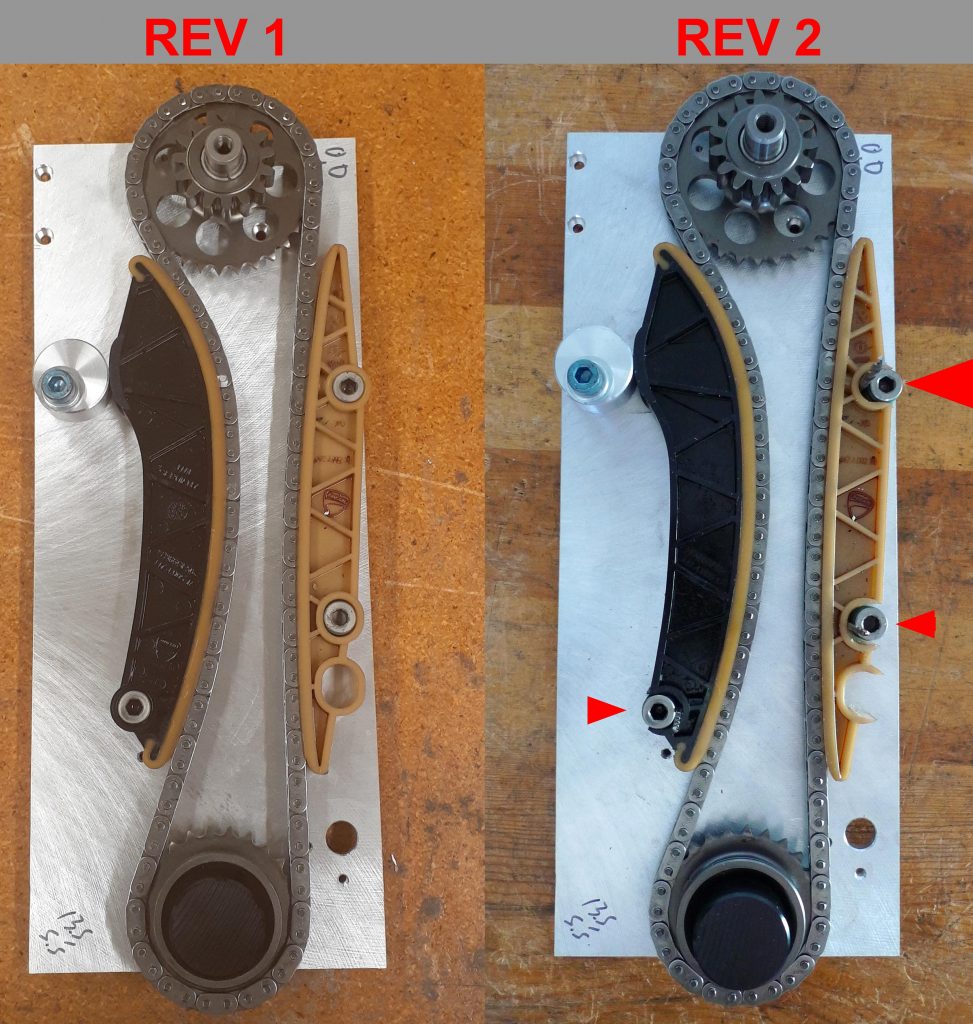

At the end of the last post, I had made a mock-up of the cam chain drive system with guides to ensure proper alignment for best performance and lowest friction. It seemed that the positioning needed some adjustment so I sent some questions to Thomas at IWIS, the cam chain manufacturer. Thomas quickly responded, highlighting the same areas I had been concerned with.

To enable some dynamic testing on the jig, I made a mandrel so that my cordless drill could spin the crank sprocket up to 1800rpm. I also cut the mounting bosses for the cam chain guides on the outboard sides of the mounts. This enabled me to use various drill bit sizes to shim both cam guides.

This is a video of the original chain guide positions. It is a little hard to discern on the video, but live you could hear a lot of mechanical noise besides the drill.

This is a video of the chain guide positions after several iterations of tweaking with various drill rods as spacers. Most of the noise is now just the drill and the motion of the chain, even when moving subtly by hand, feels the smoothest.

The end result for the pivoting guide is that I can achieve the desired geometry by moving the lower pivot point and since the upper contact is the automatic chain tensioner, I have plenty of travel to accommodate the shift.

For the fixed guide the situation is a little worse. The upper mount is located in the cylinder head, with not much possibility to move it. The lower pivot can be placed where desired, but because of the fixed upper mount location, a custom fixed guide needs to be made. It is not a complicated part, but because it is under sliding wear at high temperatures (for a plastic), it needs to be made from a rather high end plastic. Nylon 4,6 is usually the preferred choice in a production environment where the parts are injection molded, but is hard to obtain in flat stock sizes for a billet version. In this case, the easiest solution is to go with a slightly more exotic plastic, PEEK. fortunately, this material more is easily sourced so overall cost is less than the hard-to-find Nylon 4,6. A rare win-win.

Next up is testing of the oil pump drive and starter reduction gear trains. Stay tuned!