In addition to the head welding, Scott is also taking on the fabrication of the aluminum swingarm and whatever welding and heat treat fixturing required.

We had the sheet material waterjet cut by North Eastern Water Jet from 6061-T0 material. Scott is machining the billet parts from 6061-T6 and will be having the entire assembly heat treated and post machined on our 4 axis CNC mill. County Heat Treat will do the heat treat to a full T6 condition.

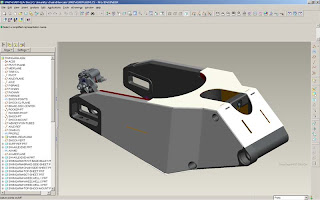

Some CAD of the finished product:

Some pictures of the parts so far:

It’s good to see so much progress taking shape on several fronts. Scott will be doing a lot of billet and welding fabrication on many chassis related parts which will free me up for the major effort that is getting the engine running.

That’s all for now.

What is the status uf the swing arm now. It has been a while since last post on its progress?

It is still progressing, although slowly. We have a couple of more billet parts in progress. Our efforts have shifted to getting the crankcase machining process moving along. Crankcase castings should be here in a couple of weeks and there is still work to be done with getting the trunnion table and Reinshaw part probing cycles finalized.