The wonders of modern technology.

From:

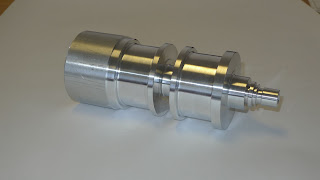

To this:

In a couple of hours. All the parts are accurate to within a few ten thousandths of an inch.

The switch from the 2024 aluminum test material to the 4340 steel part material required slowing the cutting speed by approximately 50% and increasing the feed rate by 25%. It may seem counter intuitive to increase the feed rate for a stronger material but the carbide insert’s cutting edge needs to be able to get a decent bite into the material, otherwise it just deflects the workpiece and rubs, causing a lot of heat buildup and usually insert/tool failure which leads to a scrapped part.

Now that all 3 initial pieces are machined I will change the setup in the lathe to flip the part around and accurately hold it by the features we just machined. That post will be up soon.

Good work Chris.

Yeah, CNC. I need one.