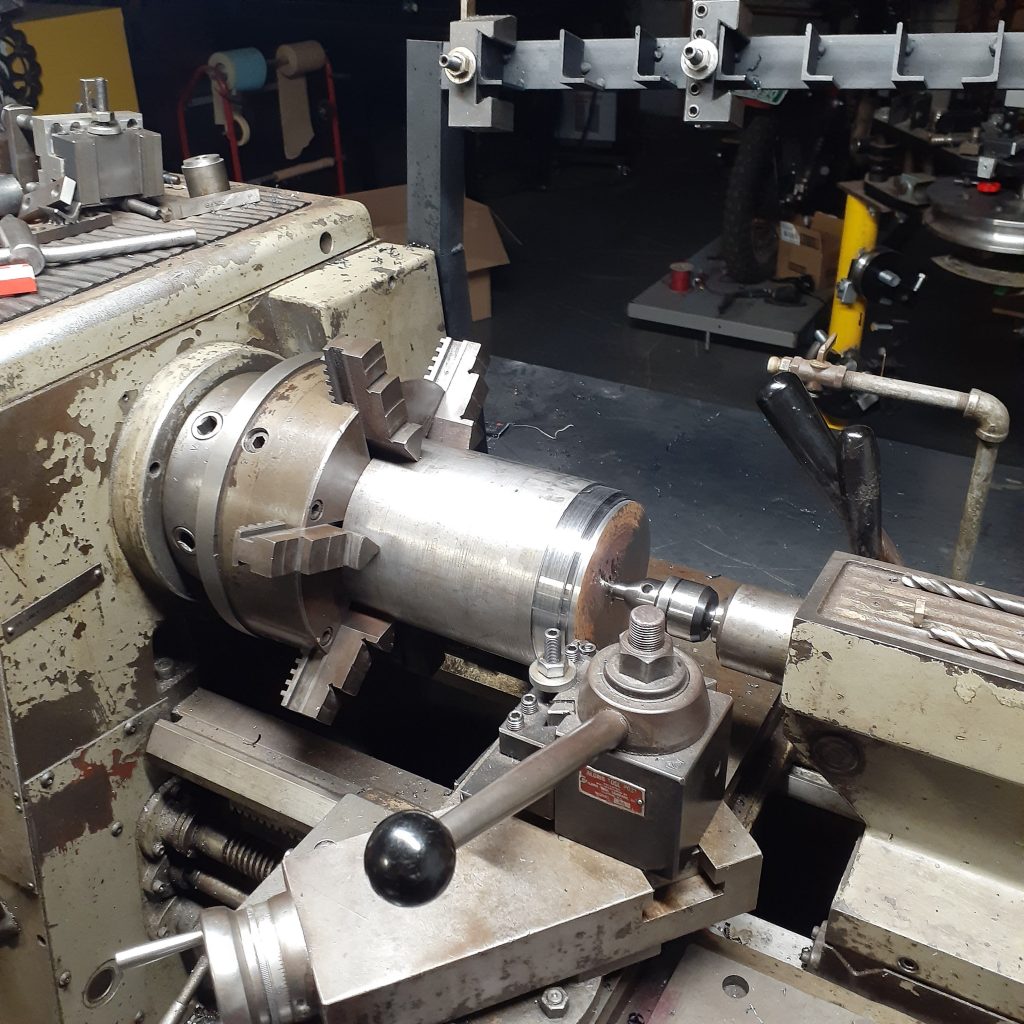

After making some good progress with the chassis castings, attention was turned back to the engine. Its time to start cutting metal for the crankshafts. I have 3 billets of 4340 vacuum melt steel in Rc28-32 condition that is just waiting for the part inside to be released. The billets are 5.5″ diameter x 7.25″ long and present a problem in how to hold for the first operation. I do have a 8″ 3 jaw chuck for the Eurotech CNC lathe, but I don’t have jaws for it and have never installed it. In the interest of getting parts made quickly and not doing machine maintenance, I decided to use my neighbor Peter’s Clausing lathe to turn a 2.375″ stub on one end of each billet. That would fit into my largest main spindle collet, allowing all further operations to be collet-based.

So I opened up his 6 jaw chuck, put a small center in the hanging end, and started turning. That picture is after about 15 minutes of machining. I’ve been used to so much aluminum machining, where it literally is like a hot knife through butter, that I seriously underestimated the time that would be needed to manually turn these parts down. Carbide inserts are nice, but unless you could flood them with coolant and have a super rigid setup, they cannot be used to anywhere near their potential.

My second option was to machine some soft jaws for the mill vise and hold it upright to profile cut the spigot. This was my second choice because the large overhang of semi-hard steel would present large cutting forces. In the end, there was no cause for concern as the vise approach, even with it mounted high my rotary trunnion table from Martin Trunnion Table.

25 minutes of unattended machining later and presto! The perfect stub for collet clamping!

Rinse and repeat and all 3 billets are ready for Op1 on the lathe, coming later this week.

The lesson for today is don’t do something yourself that you can have a machine do for you! The human touch is necessary for many subtle tasks in life, not so much for roughing out steel billets. Use it when it counts!