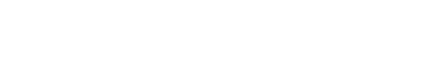

Seeing how few of the original crankcase features will be carried over to the new cases a full 3D scan of them is not necessary.

It is surprising how little information is needed. The dimensions of primary importance are:

- crank to transmission input shaft distance

- transmission shaft spacing

- crank to oil pump intermediate gear distance

- oil pump intermediate gear to oil pump shaft distance

- crank to starter intermediate gear spacing

- starter intermediate gear to starter motor spacing

- head stud bolt and pin spacing

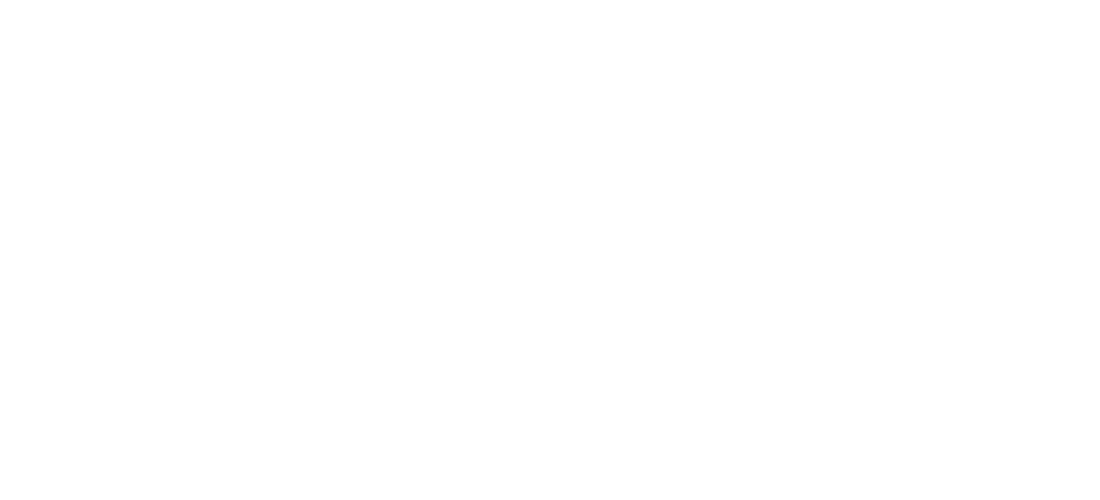

The easiest way to measure these dimensions is directly. With shafts in each bore/bearing, I mic’ed the OD of each then carefully measured the outside tangent distance. Subtracting half of each shaft diameter results in an accurate center distance measurement.

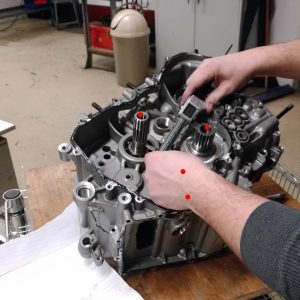

I’ll start with the primary drive side which has the primary and oil pump shaft centers.

ODs measured.

Measuring of the various centers.

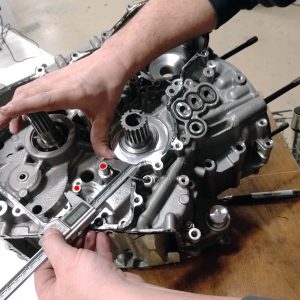

Now on to the generator side that has the starter drive shafts. Yes, a starter motor! No more lugging around a car battery and external starter to get the beast started, just press the magic button. Oh, I can’t wait!!!!!!!

The starter motor was not long enough to get a good measurement so I turned up a close fitting plug and used that instead.

Of secondary importance is the shifter drum and linkage axis locations. These are of secondary importance because if needed they can be replaced with custom components. I would prefer to use the OEM parts but if they force a more important component to move or some chassis parameter to change, then I would rather make new ones that are exactly what is needed instead of compromising.

This is not all the information that I need to design the cases, but it is all the information I need to start to design the cases!

Tomorrow I will use a Romer scanning arm to generate the profiles and mounting hole locations of the two cam chain guides and cylinder head gasket. Stay tuned!